ABOUT US

+ Vision

CAMELIA is determined to become a leading technology and trade service enterprise in Vietnam in the field of automation and digital transformation through specialized and effective solutions.

+ Mission:

CAMELIA pioneers in creating an ecosystem to increase efficiency and bring optimal value to customers, partners and employees, enhancing social responsibility and making positive contributions to the community.

TRAINING

ORIENTATION

We provide proven methodologies for digital transformation, training programs, professional advancement and digital vision for enterprises

CONSULTANT

CO-CREATION

Consulting in the development of international standard architecture, planning a roadmap and accompanying enterprises throughout the digital transformation process from surveying to implementation

COOPERATION

DEVELOPMENT

Cooperating with international IT-OT solution providers, and identifying optimal solutions that match a company's current and future needs

CAMELIA'S SERVICES

DIGITAL ENTERPRISE SERVICES

Our experienced digital transformation team works together with you to determine your company’s level of digitalization. This will be the basic for developing a digitalization strategy and a roadmap that is tailored to your requirements and business drivers

AUTOMATION SERVICES

CAMELIA cooperates with the world's leading technology corporations to provide for industry automation solutions (such as: PC base control, PLC, Robotics…) to help enterprises improve their production capacity and efficiency

LEAN MANAGEMENT SERVICES

With many years of experience in production management, CAMELIA's experts will help enterprises benefit from lean production management and improved production operation processes. This is a milestone towards digital transformation for enterprises

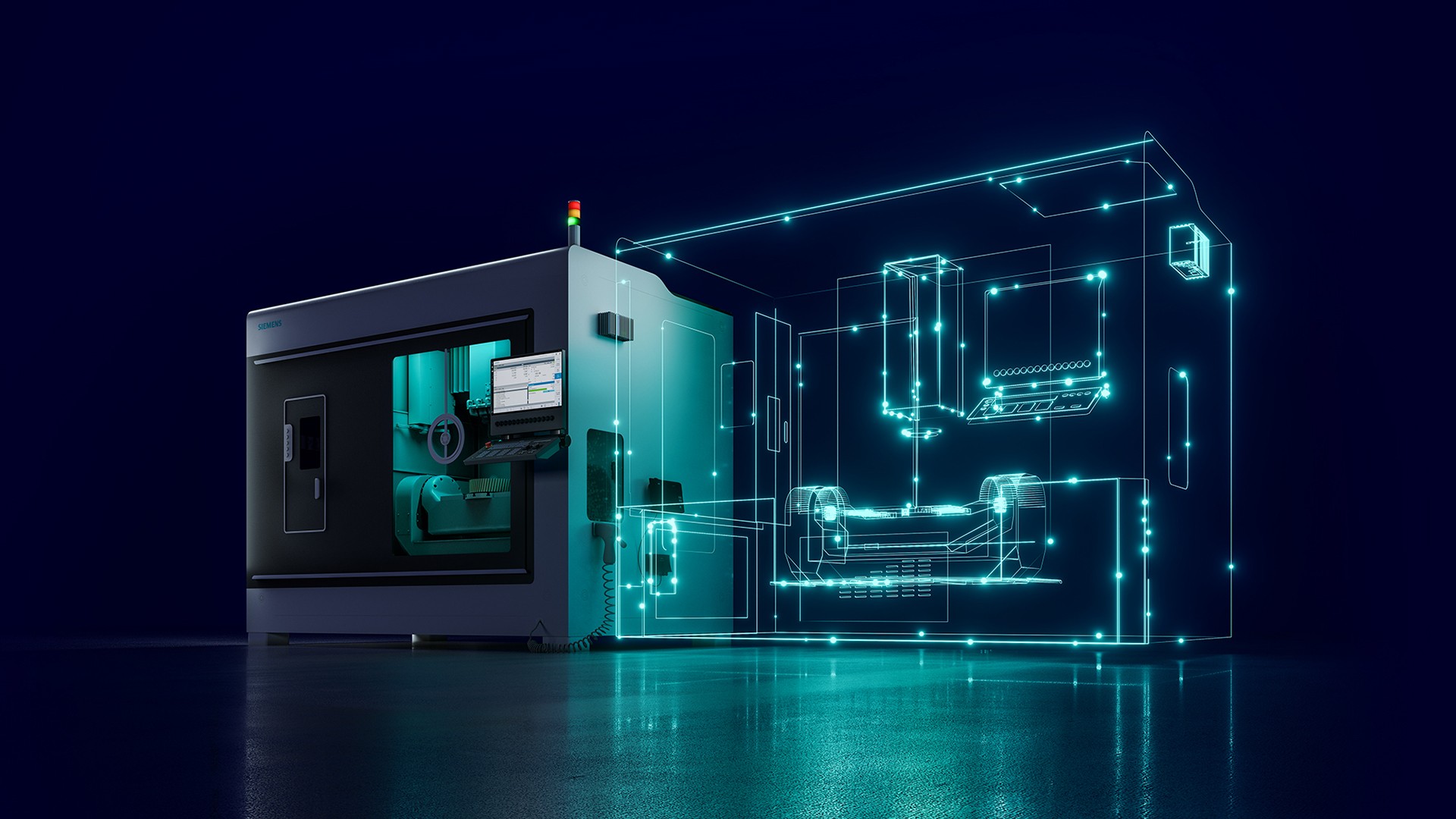

MES / IOT SOLUTION SERVICES

CAMELIA cooperates with the world's leading partners in IOT and MES systems to help enterprise visualize production activitives and manage production in real time

ENGINEERING DESIGN SERVICES

CAMELIA's experts in consulting and designing the industrial products help enterprise reduce investment cost for R&D activities and increase operational efficiency when launching commercialized products in accordance market demand

IT INFRASTRUCTURE SERVICES

We have specialists with deep knowledge in the field of planning and designing IT infrastructure in manufacturing plants. We accompany enterprises to build IT systems in line with their goals and resources

IMPLEMENTATION PROCESS

Consulting

We work with you to set goals and identify the action areas to optimize your production. If necessary, we perform a technical review of your plant and its system architecture. This lets us identify all the potential for digitalization. The end results is a digitalization strategy tailored to your needs and a roadmap for implementation. Your digital transformation starts here.

Check

With Digitalization Check as a Service we analyse your database and evaluate your hardware. We ensure that your machines are optimally connected to the IT systems. In doing so, we rely on standardized and scalable solutions. The result is an implementation plan to increase the digitization capability of your systems.

Preparation

Based on the digitalization check we upgrade your machine tools to state of the art (software updates, hardware upgrades or hardware retrofits). The necessary connectivity can be achieved at that point.

Implementation

The next stage is implementation: We install the necessary software modules, configure them to your requirement, test them and put them into operation. We also connect your machines to the higher-level IT system. By doing so you have access to your data whenever you need. This transparency forms the basis for further analysis. Our training programs ensure your employees can get the best out of the new applications.

Analysis

Discover optimization potential and improve your overall equipment effectiveness (OEE). For example, OEE is tracking using a monitoring system to ensure continuous optimization of production. We help you to develop customer-specific dashboards and to perform data analysis. Moreover, we show you ways to use this knowledge to your advantage and thus extend the service life of your machines, save costs, and improve quality.

Optimization

We provide the right solutions for you to fully exploit the potential for optimizing your machines – and turn them into specific benefits for your production system. The main elements here are services like spare parts and repair services, service agreements, modernization activities such as upgrades, retrofitting, and productivity improvement.

Maintenance

We provide the maintenance of your IT systems and machines. That’s why we have expanded our traditional range of services to include digitalized add-ons for remote support, increased machine transparency, proactive error analysis, and faster troubleshooting. Our database management and software updates ensure your IT system offers maximum availability. You have peace of mind and focus on your core business

READY-TO-IMPLEMENT SOLUTION

Manufacturing Execution Systems (MES) are software solutions that ensure quality and efficiency are built into the manufacturing process and are proactively and systematically enforced

We round up some of the most innovative and trailblazing industrial companies across the landscape of the industrial Internet of Things.

Building H in Wuhan was designed with green buildings in mind from the outset. The open control technology from Beckhoff made it easy to integrate all equipment into the building management system developed by Dongfeng Design Institute. A digital building twin now provides capabilities for self-diagnostics, self-analysis and even autonomous decision-making.

Success through trust, openness and a culture of innovation Our corporate culture is characterized by the family values we hold as an owner-managed technology company and our strong roots in East Westphalia. Long-term, cooperative relationships with our employees and customers play a central role in

Success through trust, openness and a culture of innovation Our corporate culture is characterized by the family values we hold as an owner-managed technology company and our strong roots in East Westphalia. Long-term, cooperative relationships with our employees and customers play a central role in